Tesla Model S: Driveshaft Assembly - LH (Remove and Replace)

Warning: If the vehicle has air suspension, activate "Jack" mode on the touchscreen before raising and supporting the vehicle.

Special tool(s) required for this procedure:

| Supplier | Part Number | Description |

| Tesla | 1000991 | Axle Extractor Note: Use 1000991 for a large drive unit only. |

| Tesla | 1057312-00-A | Axle Extractor Note: Use 1057312-00-A for either a large or small drive unit. |

| Tesla | 1082171-00-A | S-hook |

- Position the vehicle in preparation for raising it, but keep the vehicle at ground level at this time.

- Ensure that the transmission is in Park.

- Remove the wheel center cap.

.png)

- Remove the hub nut (torque 245 Nm).

.png)

- Remove the wedge-lock washer.

- If the vehicle has air suspension, use Toolbox to depressurize the air spring back to the reservoir (refer to procedure).

- Sit in the driver's seat, but leave the driver's door open.

- On the touchscreen, touch Controls > E-Brake and Power Off.

- If there is an option for "Tow Mode", select it and skip to step 15. If not, continue with this procedure. Warning: Once "Tow Mode" is selected, the vehicle is in Neutral.

- Press and hold the brake pedal through step 14.

- On the touchscreen, touch "Press here for Neutral".

- On the touchscreen, touch "Power Off". A confirmation box appears.

- Touch "Power Off" on the confirmation box. The center screen turns off.

- Continue holding the brake pedal until hearing the sound of the contactors opening. Warning: The vehicle is now in Neutral.

- Raise and support the vehicle (refer to procedure). Warning: Do not work on an incorrectly supported vehicle. Warning: To avoid serious injury, use appropriate equipment to carry out this operation.

- Remove the mid aero shield (refer to procedure).

- Using a suitable tool, ease the brake caliper pistons and pads away from the rotor.

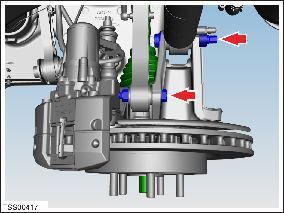

- Remove the bolts (x2) that secure the brake caliper to the knuckle (torque 120 Nm).

- Release the caliper and use the S-hook to support it.

Caution: To avoid damage to the brake line, the brake caliper must be supported at all times.

.png)

- Disconnect the electric parking brake harness connection.

.png)

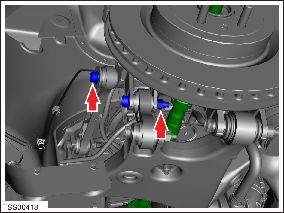

- Remove the bolt that secures the upper suspension link to the knuckle (torque 140 Nm).

- Remove the nut and bolt that secure the air spring module to the

knuckle (torque 140 Nm).

- Remove the bolt that secures the toe link to the knuckle (torque 130 Nm).

- Remove the nut and bolt that secures the integral link to the

knuckle (torque 130 Nm).

- Tap the exposed end of the driveshaft with a nylon mallet to release it.

- With assistance, swing the brake rotor and knuckle assembly

outward and release the outer driveshaft spline from the rear hub,

using a driver to disengage the axle from the hub splines.

- Tie the brake rotor and knuckle assembly aside for access.

- Use the axle extractor tool to release the driveshaft from the

transmission.

Caution: Ensure that the axle extractor tool does not contact any of the differential retaining studs.

- Carefully withdraw the driveshaft assembly from the vehicle.

Caution: To avoid damage to the driveshaft boots and oil seals, exercise caution when removing and installing drive shafts.

Caution: Plug the transmission opening to prevent ingress of dirt or moisture.

Note: Place suitable absorbent material around the affected area to absorb any fluid spillage.

Warning: Only use cleaning agents and solvents in a well-ventilated area.

Caution: Only fully tighten suspension nuts and bolts when the vehicle is on a 4-post lift and the suspension is in the ride height position.

Note: Clean the affected areas before installation.

Caution: Ensure that the bolt that secures the spring assembly to the knuckle is inserted towards the rear of the vehicle; the head of the bolt faces the front of the vehicle and the nut is tightened at the rear. Caution: Ensure that the new driveshaft has a snap-ring already installed. If it does not, then install a different driveshaft that has a snap-ring already installed. Return any driveshafts without a snap-ring using the MRB process. Do not remove or reuse snap-rings.

- Apply approximately 1 gram of Molykote M-77 Lubricant Paste

to the outboard side of the driveshaft to the hub mating face.

- When installing the driveshaft into the drive unit:

- Ensure that the opening of the snap ring is facing towards the bottom of the drive unit.

- Do not damage or displace the oil seal.

- Verify that the driveshaft is fully seated by carefully pushing it into the drive unit until there is an audible "click" from the snap ring.

- After connecting the electric parking brake caliper harness, wrap the connector seam with electrical tape to prevent dirt ingress.

- Pump the brake pedal at least 5 times to seat the pads against the brake rotors.

Warning: Always check that the brake pads are seated correctly before driving the vehicle.

- Repressurize the air spring.

- Transfer the vehicle to a 4 post lift (refer to procedure).

- Perform a four wheel alignment check (refer to procedure).

- Check for proper operation of the electronic parking brake.