Tesla Model S: Oil Seal - Differential to Driveshaft Assembly - LH (Remove and Replace)

Special tools required for this procedure:

| Supplier | Part Number | Description |

| Tesla | 1051509-00-A | Output Seal Installation Tool |

| Tesla | 1052583-00-A | Seal Puller Note: Technicians may use this tool or equivalent. |

| Tesla | 1057312-00-A | Axle Extractor |

- If the vehicle has air suspension, use Toolbox to depressurize the air spring back to the reservoir (refer to procedure).

- On the touchscreen, touch Controls > E-Brake and Power Off > Tow Mode. Warning: Once "Tow Mode" is selected, the vehicle is in Neutral.

- Remove the road wheel (refer to procedure).

- Remove the mid aero shield (refer to procedure).

- Drain the gearbox fluid (refer to procedure). Note: It is not necessary to drain the gearbox fluid if the vehicle is level throughout this procedure.

- Disconnect the toe link from the LH knuckle (torque 130 Nm).

- Disconnect the upper link from the knuckle (torque 140 Nm).

- Remove the park brake caliper (refer to procedure).

- Release the wheel speed sensor harness from the securing clip

and bracket.

- Disconnect the shock absorber from the knuckle (torque 140 Nm).

Tip: If necessary, use a pry bar or drift punch to align the lower shock bushing while removing the bolt.

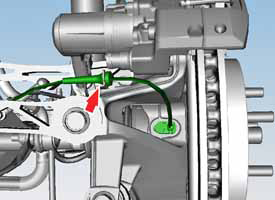

- Use the axle extractor tool to release the driveshaft from the

transmission. Rest the driveshaft on the lower control arm.

Caution: Ensure that the axle extractor tool does not contact any of the differential retaining studs.

Caution: Do not strain the brake hose or electrical wiring while pulling the knuckle.

Note: Place suitable absorbent material around the affected area to absorb any fluid spillage.

- Protect the driveshaft's output flange oil seal face and spline to prevent damage.

- Using 1052583-00-A or an equivalent seal puller, remove the output shaft oil seal from the differential casing.

Caution: Plug the transmission to prevent ingress of dirt or moisture.

Installation procedure is the reverse of removal, except for the following:

Caution: Ensure that the mating faces are clean and free from debris.

Caution: Do not reuse the snap-ring. Install a new snap-ring before reinstalling the driveshaft.

Caution: Ensure that the bolt that secures the spring assembly to the knuckle is inserted towards the rear of the vehicle; the head of the bolt faces the front of the vehicle and the nut is tightened at the rear.

Tip: It might be helpful to lift the lower control arm with a floor jack to line up the rear suspension during reassembly. Do not torque the bolts at this time.

Caution: Only fully tighten suspension nuts and bolts when the vehicle is on a 4-post lift and the suspension is in the ride height position.

- When installing the driveshaft into the drive unit:

- Ensure that the opening of the snap ring is facing towards the bottom of the drive unit.

- Do not damage or displace the oil seal.

- Verify that the driveshaft is fully seated by carefully pushing it into the drive unit until there is an audible "click" from the snap ring.

- Check and top up gearbox fluid.

- Check the differential casing oil seal register for burrs and other damage.

- Using the 1051509-00-A output seal installation tool, install a new output shaft oil seal.