Tesla Model S: Bushing Removal, Front Motor Mount

Warning: To avoid personal injury, eye protection must be worn when performing this operation.

Warning: To avoid personal injury, safety-toe shoes and cut-resistant gloves are recommended when performing this operation.

Note: A demonstration video for removing and replacing the drive unit bushing can be found on the Tesla Academy training site. It is listed as TAS-DU-BUSHING-OLT-01_EN: Model S Drive Unit Bushing Removal Video.

The drive unit bushing tool set includes the following parts:

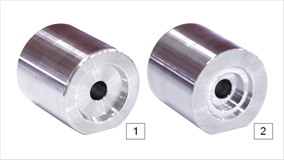

| 1 | Driver |

| 2 | Front bushing cup |

| 3 | Rear bushing cup |

| 4 | Nut bearing assemblies |

| 5 | Threaded rod |

Note: The front motor mount only permits removal and installation from 1 side of the mount. Remove and install the bushing only in the direction shown.

- Remove the drive unit (refer to procedure).

- Use brake cleaner to clean the threaded rod and the nut bearing assemblies.

- Use 3M Spray Lube 08878 or equivalent to lubricate the threaded rod and the nut bearing assemblies.

- Thread 1 nut bearing assembly onto 1 end of the threaded rod.

- Slide the closed end of the front bushing cup onto the other end

of the threaded rod.

- Slide the other end of the threaded rod through the left side of

the front bushing.

- Slide the driver onto the other end of the threaded rod so that

the side of the driver with the single tapered counterbore faces the

bushing and the flat side is angled in line with the side of the

drive unit.

Note: A gap between the taper on the bushing driver and the bushing is normal. The bushing compresses as the nut bearing assemblies are tightened.1 Faces bushing 2 Faces nut bearing assembly

- Thread the second nut bearing assembly onto the other end of the threaded rod until it lightly touches the driver.

- Adjust the assembly until the front bushing cup is seated flush against the front motor mount.

- Place a 1 in (24 mm) ratchet wrench onto each nut bearing assembly.

- Alternate rotating the ratchet wrenches to push the driver

towards the front bushing cup until the bushing is removed into the

bushing cup.

Caution: If the effort required to rotate the ratchet wrenches is excessive, the tool is misaligned and continued ratcheting could cause damage. Loosen the nut bearing assemblies on the threaded rod, add lubrication to the threaded rod, realign the parts, and begin again.

- Remove the tool and the bushing from the front motor mount.

- Disassemble the removed tool. Discard the bushing.